|

|

|

|

The story is told that, about a thousand years ago, in China,

a prison guard invented the woven bridge.

The main surviving evidence of this concept is a 900 year old 2 ft. x 17 ft. painting

of the Qing-ming Festival on the Bian River, and little else.

The span of this bridge was 60 ft. with a 30 ft deck and a height of 14 ft.

|

|

|

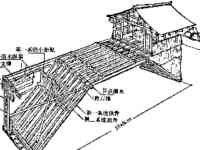

No plans or structural descriptions of this bridge appear to have survived

except for the odd tantalizing tid bit, like this drawing,

and the design appears to have been forgotten

when the last bridge reached the end of its life.

Recently this ancient bridge has attracted renewed interest

and you'll find quite a few pages on the web, discussing it.

|

|

In February 2000 PBS, in its NOVA "Lost Empires" series, first broadcast

China Bridge

and I was hooked by the concept.

|

|

|

Trying to build bridges with bamboo lashings and logs is obviously not of practical, modern use

but I was sure the concept could be exploited today, if only I could work out the bridge's secrets

and translate them into present day construction materials and techniques.

|

|

|

I spent almost a year, looking for magic ratios in the geometry, golden rules, etc.,

thinking it unlikely that the Chinese built log bridges with a lot of fancy trigonometry.

|

|

|

Finally I decided there were no magic numbers, and why should there be? Lumberyards

with predictable, dimensioned lumber hadn't been invented yet, so you just get some logs from the area, lay them out on the ground, cut them to fit,

and you have another unique bridge standing.

|

|

|

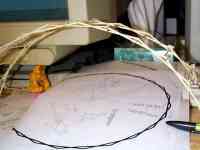

With toothpicks, barbeque skewers, popsicle and chop sticks,

I made models to touch and bend until I started to get a feel for the design.

My aim was to build a bridge out of the least possible number of simple parts,

that only have to be duplicated, to make a bridge.

The parts should also be scaleable for differing spans and load requirements.

Another year went by, working out the formulas required to produce component dimensions

for all possible geometries, using readily available dimensioned lumber,

for spans up to 50 feet, with various load capacities.

|

|

|

Only early in 2002 was I able to remove the last fudge-factor in my calculations

and reduce the number of all required parts for any arch to 2,

with no additional parts required to nail on the decking.

|

|

|

The intricacies of this concept are mind boggling and not necessarily of interest

to many but, if your interest runs in the mechanical direction,

you may note that all components do double and triple duty.

The individual arch component consists of 2 identical pieces, which prevents defects

in the lumber used, from having a serious impact on the structural strength of the arch.

Mating these two pieces also automatically creates a lap joint that can clamped by the same bolt

that holds the joists and hand rail posts.

|

|

|

The joists that span the arch peaks are paired for the same reason and symetrically,

not only distribute point load over the arch, but also provide additional strength

by completing the intermediate arch triangles to create a curved truss.

The cross-beams are now merely a set-up aid and, once decking is applied,

perform no significant structural function. They may still transfer a bit of serious overload

to the component underneath, slightly distorting the triangle in which they sit, maintaining flexibility in the arch

and distributing stress. They may also be extended to hold railing post braces.

|

|

|

For safe load calculations I use 1/400 span deck deflection. In other words,

if the deck of a 400" (33 foot) span does not bend more than an inch,

it is a safe load with a 3x safety factor. As I have bent bridges 1/40 span (10 times 1/400),

with no damage whatsoever, I'm confident that sudden failure is not possible

because the deck deflection would scare an abuser long before the bridge failed.

|

|

|

Except for a superficial resemblance, my design has evolved into a quite different structure from the

original Chinese Rainbow Bridge. Of course the bamboo lashings have been replaced with bolts

but my arch components don't need to be woven into a precarious "house of cards",

one piece at a time.

|

|

|

In the original Chinese design, there appears to be no evidence that the arch component crossings were fixed together,

so the entire structure was truly woven, like a basket,

requiring all the parts to be completely assembled before they become functional.

Much of the load appears to be carried by the cross-beams,

that transfer the load to the middle of the arch component underneath,

which is the least efficient method of distributing load over the arch.

No real triangles are formed in the arch.

|

|

|

With the luxury of square lumber and fixing the arch component crossings,

my design creates a series of solid triangles that are bridged by a joist, forming a curved truss,

which is not only many times more efficient but eliminates the need for transverse bracing to ensure lateral stability,

as the deck planking will usually suffice to perform that duty.

2 or more arches of my design, will not only stand solidly, without any braces or footings,

but will actually support their full design load, without suffering any damage.

Of course a properly erected arch bridge requires solid footings to enjoy safe and long use,

but this is just another testament to the strength and flexibility of this design.

|

|

|

A gratuitous benefit of my radial design is that the span need not be level.

Even with an appreciable difference in elevation, between the two ends of the bridge,

everything works and looks good.

|

|

|

Bridges normally weigh much more than the live load they are capable of carrying.

This design will actually support many times its own weight, without failing.

This 3' model, built entirely from soft, 1/4"x3/4" cedar lath, for example,

easily holds both girls even though it's only pinned together with a dozen brads,

not properly assembled, and a bit wobbly with 226 lbs. on it. The bridge model weighs 3.5 lbs.

|

|

This 18" model is built from 3/32" x 1/4" (6mm x 2mm) oak and holds over 140 lbs. and weighs less than 150g (5 oz.)

| |

|

|

I don't believe it is possible to build a stronger bridge

with fewer parts and less lumber.

|

|

|